With the rapid development of automotive industry, people put forward higher and higher requirements for automotive resistance to external environment and reliability, stability, corrosion resistance and appearance aesthetics of automotive long-term operation. Automobile damage mainly includes accident damage, wear damage and corrosion damage, among which corrosion damage is serious. Metal materials are the main materials used in automobiles, and corrosion problems generally exist in metal materials. Zhuge repair network 2.0 on-line tells you that the corrosion of metal surface of automotive parts not only destroys the appearance of the car, but also directly affects the service life of the car, at the same time, it brings environmental pollution, accidents and waste of materials and energy.

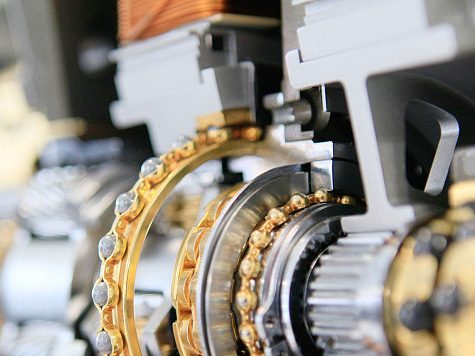

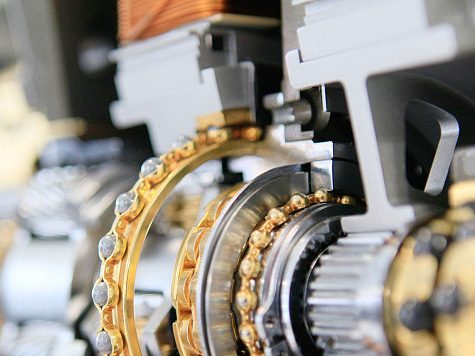

For this reason, every finished car manufacturer has to undergo metal surface treatment. In addition to the three main moving parts of automotive engine, such as piston, piston ring and connecting rod, which we are familiar with, electroplating treatment is needed for the bearing bush, intake and exhaust valves, exhaust bars, *, shock absorber connecting rods and other parts, and even the decorative parts of automobiles need surface treatment to improve their aesthetics.

The commonly used surface treatment methods for automobiles are as follows:

(1) Electrochemical treatment: electroplating and anodizing

(2) Painting: Spraying, Electrophoresis

(3) Chemical treatment: phosphating, passivation, blackening, etc.

(4) Heat treatment: hot dipping, hot spraying, hot stamping, chemical heat treatment, etc.

(5) Vacuum method: evaporation plating, sputtering plating, ion plating, etc.

Automotive parts and components are the important foundation to support the healthy, stable and rapid development of the automotive industry. It is of great significance to develop China's automotive parts and components industry. But at present, there are still many shortcomings in automotive parts in China. If we want to change the current situation of insufficient development power and weak core competitiveness of automotive parts industry in China, we must rely on technological innovation to comprehensively enhance the technological competitiveness of domestic automotive parts from the aspects of material, process, design and manufacturing. Electroplating technology is the necessary guarantee for the quality of automotive parts.

Auto parts electroplating can be divided into three categories according to their functions:

(1) Protective coating: also known as corrosion-resistant plating, the parts themselves are required to have good corrosion resistance. It accounts for 70%~80% of the total electroplating area of automobiles, such as galvanizing, galvanizing alloy, lead plating and so on.

(2) Protective and decorative coatings: The automotive industry has strict requirements for protective and decorative coatings, which require bright appearance, uniform tone and good corrosion resistance after plating. The coatings require no color change and stainless corrosion for 5 to 10 years, such as copper plating, imitation gold, copper+nickel+chromium, etc.

(3) Functional electroplating: Functional electroplating is different from the first two plating, which mainly gives special physical and chemical properties to the matrix material, focusing on the characteristics of the coating itself. Such as lead-tin alloy, hard chromium plating, tin plating, etc.

On November 3, the "Recommendations of the CPC Central Committee on the Thirteenth Five-Year Plan for National Economic and Social Development" put forward that low-carbon development of transportation should be promoted, priority should be given to public transport, construction of rail transit should be strengthened, and green travel such as bicycles should be encouraged. Implement the new energy vehicle promotion plan to improve the industrialization level of electric vehicles.